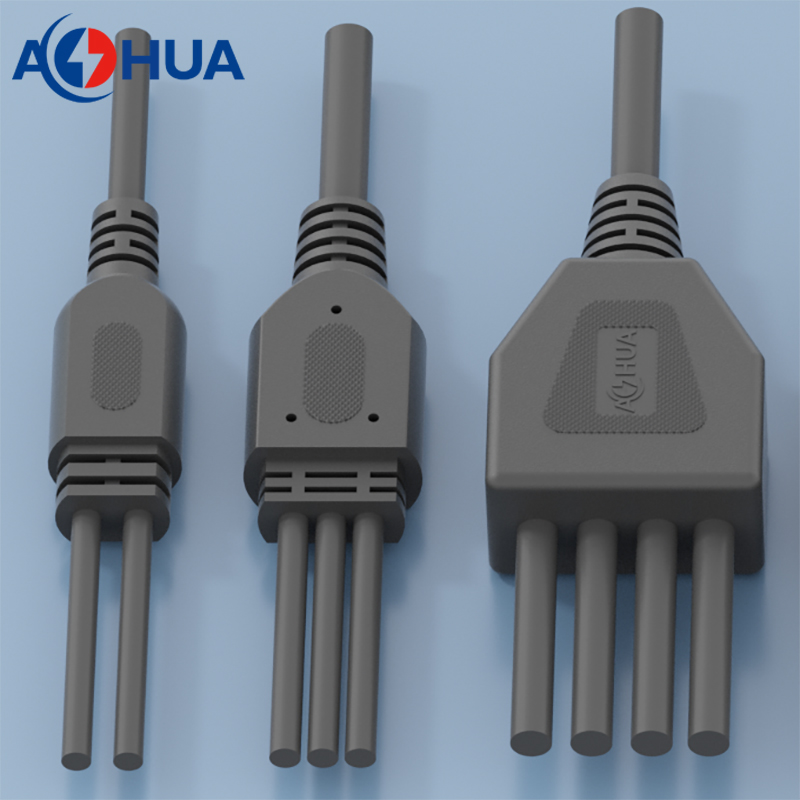

AOHUA Junction Box Waterproof Plug Sockets For Power Signal Cable Solution Customized

With the developing over 18 years’ experience, AOHUA have becoming a one stop ODM OEM manufacturer for waterproof cable solutions.

There are many series waterproof plug sockets for different applications all over the world. Under different application conditions, we can design & produce different solutions to meet your requirements. Such as, for outdoor led lighting, we can design favorable waterproof cable solutions; for hard or seafood feeding system, we can make high quality waterproof plugs sockets solutions; for indoor plant grow lighting, we can design the integration cable solution and make high quality products for you.

If you require waterproof plug sockets for a power signal cable solution customized to your specific needs, there are a few approaches you can consider. Here’s a general framework to help you navigate the process:

- Determine your requirements: Start by understanding the exact specifications and requirements for your waterproof plug sockets. Consider factors such as voltage, current, cable diameter, environmental conditions, and the level of waterproofing needed.

- Research available options: Explore the market for existing waterproof plug socket solutions. Look for suppliers or manufacturers that specialize in waterproof electrical connectors or custom cable assemblies. This can be done through online searches, industry directories, or by seeking recommendations from professionals in the field.

- Contact suppliers: Reach out to the selected suppliers to discuss your specific needs. Provide them with detailed information about your requirements, including the desired waterproofing rating, the type and size of the cables, and any other relevant specifications. This will allow them to assess whether they can offer a customized solution.

- Request customization: If the suppliers have off-the-shelf products that meet your requirements, you can inquire about customization options. Alternatively, if they don’t have suitable products, discuss the possibility of creating a custom solution tailored to your needs. Provide them with as much information as possible, including drawings, diagrams, or samples if available.

- Evaluate proposals: Review the proposals received from different suppliers, considering factors such as cost, lead time, quality, and the supplier’s expertise in waterproof connectors. Request samples or prototypes to assess the functionality and compatibility of the proposed solution with your power signal cable system.

- Testing and validation: Once you receive the customized waterproof plug sockets, perform thorough testing and validation to ensure they meet your requirements and adhere to the specified waterproofing standards. This may involve conducting electrical tests, immersing the connectors in water, and evaluating their performance in various environmental conditions.

- Installation and maintenance: After selecting the appropriate solution, follow the installation instructions provided by the supplier. Ensure proper sealing and integration with your power signal cable system. Additionally, establish a maintenance plan to ensure the continued performance and longevity of the waterproof plug sockets.

Remember, for complex or critical applications, it’s advisable to consult with a qualified electrical engineer who can provide expertise and guidance throughout the customization process.

Start your high quality and reliable waterproof plug sockets solution customized, contacts our sales Molly via email: molly@aohuadz.com. Website: www.aohuadz.com