How Much You Know About Waterproof Power Connectors–Customized Solutions for Reliable Connections

Waterproof power connectors play a crucial role in various industries where reliable and secure electrical connections are needed in harsh and demanding environments. These connectors are designed to provide protection against water, dust, and other environmental factors, ensuring uninterrupted power supply and preventing electrical failures. In this article, we will explore the basics of waterproof power connectors, the benefits of customized solutions, and the design and production process.

Basic Connector Features:

- Waterproof power connectors feature several key elements that contribute to their effectiveness in harsh conditions:

- Sealing: These connectors are equipped with seals or gaskets that create a water-tight barrier, preventing moisture ingress and maintaining the integrity of the connection.

- Material: High-quality materials such as durable plastics, rubber, or metal alloys are used to construct the connectors, providing resistance to corrosion, UV radiation, and extreme temperatures.

- Locking Mechanism: To ensure a secure connection, waterproof connectors often incorporate locking mechanisms that keep the mating halves firmly together, even in high-vibration environments.

With different industries and applications having distinct requirements, the ability to customize waterproof power connectors is essential. Customization allows for tailored solutions that precisely meet specific needs, leading to enhanced performance, efficiency, and longevity. Manufacturers specializing in waterproof connectors offer customization options that include:

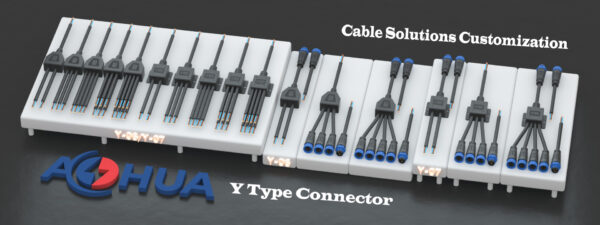

- Connector Types: There are various connector types available, such as circular connectors (e.g., M8, M12), rectangular connectors (e.g., D-Sub), or specialized connectors for specific industries (e.g., aviation, medical).

- Pin Configurations: Customized power connectors can be designed with specific pin configurations to match the power requirements, allowing for accurate and efficient power transmission.

- Cable Lengths and Gauges: Depending on the application, customized cables can be manufactured with precise lengths and gauges, ensuring proper fit and optimal electrical performance.

Design and Production Process:

Designing and producing customized waterproof power connectors involves a comprehensive process that ensures the final product meets the specific requirements of the application. Here are the key steps involved:

- Requirement Analysis: Collaborate with the manufacturer to define the precise requirements, considering factors such as environmental conditions, voltage and current ratings, installation constraints, and industry standards.

- Conceptual Design: Based on the requirements, develop a conceptual design that outlines the connector’s form, pin layout, locking mechanism, and sealing methods. The manufacturer can provide expertise in optimizing the design for waterproofing and electrical performance.

- Prototyping and Testing: Create prototypes of the customized connectors for testing and validation. This phase allows for iterative improvements and ensures the connectors meet the performance and waterproofing standards required for the application.

- Certification: Seek necessary certifications and compliance based on the industry standards or regulatory requirements relevant to the specific application. This may involve electrical safety certifications or waterproofing tests conducted by reputable laboratories.

- Mass Production: Once the design and testing stages are successful, proceed with mass production. Work closely with the manufacturer to establish production timelines, quality control measures, and ensure consistent adherence to design specifications.

Customized waterproof power connectors provide reliable and secure electrical connections in demanding environments. By opting for tailored solutions, various industries can ensure seamless power transmission while protecting against the damaging effects of water, dust, and other environmental factors. Collaborating with a reputable manufacturer with expertise in waterproof connectors is crucial to designing and producing connectors that meet the specific requirements of the application, leading to enhanced performance, longevity, and overall satisfaction.