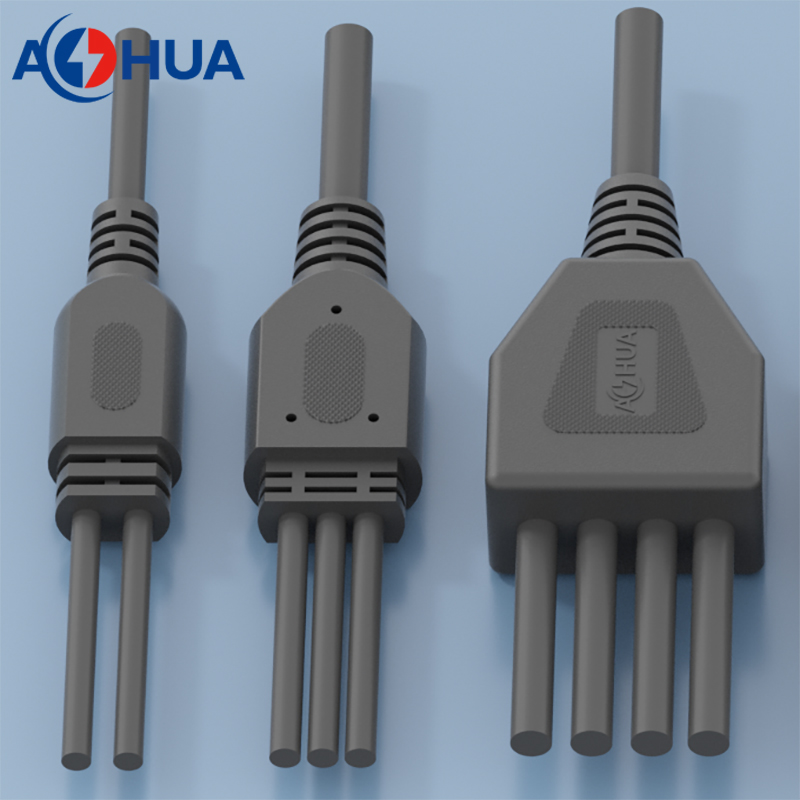

Shenzhen Manufacturer AOHUA Customizing Waterproof Electrical Y Connectors for Outdoor Power Applications

AOHUA is a manufacturer of prorducing cable waterproof connectors solution since 2008. With more than 17 years’ developing, we have becoming a super manufacturer that we can design and produce the whole cable solution from raw material to products. In this article we mainly talk about the Y connector customization.

In outdoor power applications, such as garden lighting or outdoor signage, it is crucial to ensure the electrical connections are weatherproof to prevent damage and ensure safety. One way to achieve this is by customizing waterproof electrical Y connectors that can withstand the elements. This article will explore the process of customizing such connectors for outdoor power applications.

-

Understanding the Requirement:

Before customizing waterproof electrical Y connectors, it is essential to understand the specific requirements of the outdoor power application. Consider factors such as the voltage and current requirements, the type of wiring being used, and the environmental conditions the connectors will be exposed to. Understanding these details will help determine the appropriate materials and design for the customized connectors. -

Selecting the Right Materials:

Choosing the right materials for the waterproof Y connectors is crucial for their performance and durability. Look for materials that are resistant to UV radiation, moisture, and temperature fluctuations. Silicone, polypropylene, and PVC are popular choices for outdoor applications. Additionally, ensure that the materials meet industry standards and have appropriate safety certifications. -

Designing the Connector:

The design of the waterproof Y connector should consider both functionality and ease of installation. The connector should have secure cable clamps to provide strain relief and prevent cable damage. It should also incorporate locking mechanisms or gaskets to create a watertight seal. Pay attention to the connector’s size and shape, ensuring it fits well within the intended installation environment. -

Testing and Certification:

Thorough testing is essential to ensure the functionality and safety of the customized waterproof Y connectors. Conduct tests to evaluate their resistance to water, dust, temperature variations, and mechanical stress. Seek certification from recognized authorities to validate compliance with industry standards, such as the IP (Ingress Protection) rating system. -

Installation and Maintenance Guidelines:

Provide clear installation and maintenance guidelines to ensure proper use of the customized connectors. Include instructions for preparing the cables, connecting the wires, and securely sealing the connectors. Emphasize routine inspection and maintenance to identify and resolve any issues promptly.

Customizing waterproof electrical Y connectors for outdoor power applications is crucial to ensure reliable and safe electrical connections. By understanding the requirements, selecting the right materials, designing for functionality, testing rigorously, and providing installation guidelines, a customized waterproof Y connector can withstand the elements and fulfill its purpose in outdoor environments effectively.