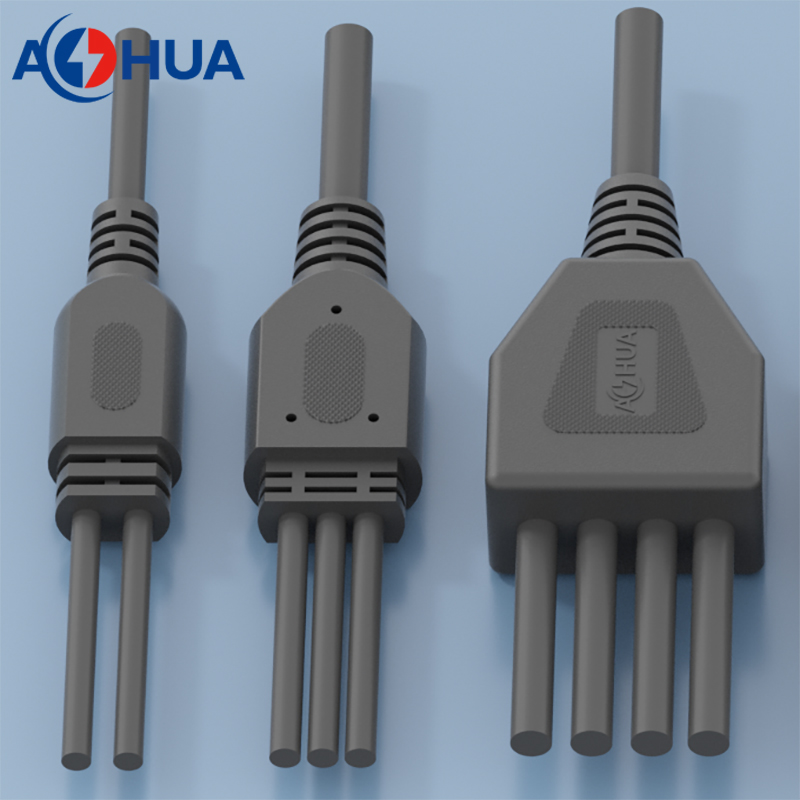

Horticulture LED Light Waterproof Power Wire Assembly with 3-Pin M16 Connector

Premium Connectivity for Demanding Grow Environments

Engineered for reliability and peak performance in commercial and hobbyist horticulture applications, this LED Light Power Wire Assembly is the definitive solution for connecting your grow lights. Featuring a robust 3-pin M16 waterproof plug and socket set, this assembly is built to ensure a safe, stable, and efficient power delivery to your LED fixtures, season after season.

Key Features & Benefits:

-

UL Approved Components: Guarantees that the connector meets rigorous US safety standards for electrical components, providing peace of mind and ensuring compliance for professional installations.

-

Superior M16 Waterproof Design (IP67/IP68 Rated): The threaded coupling mechanism and integrated sealing O-ring create a dust-tight and waterproof seal, protecting the connection from moisture, humidity, nutrient spills, and high-pressure wash-downs—common challenges in any grow room or greenhouse.

-

3-Pin Configuration for Full Spectrum Control: The three distinct pins allow for separate connections for Active/Live, Neutral, and Ground wires. This is essential for safely powering advanced horticulture LEDs that require a dedicated earth ground for safety and performance.

-

Gold-Plated Copper Contacts: The pins are crafted from high-conductivity copper and finished with a corrosion-resistant gold plating. This ensures minimal voltage drop, superior signal integrity, and a stable connection that resists oxidation and arcing, even in high-humidity environments.

-

High-Temperature PA66 Plastic Housing: The plug and socket bodies are molded from PA66 (Nylon 66), a premium engineering plastic known for its exceptional mechanical strength, high heat resistance (withstanding grow light temperatures), and excellent chemical resistance against fertilizers and cleaning agents.

-

Pre-Wired for Easy Installation: The assembly comes with flexible, high-strand copper wire leads, pre-soldered and insulated for a secure and permanent connection. This saves significant installation time and ensures a professional, reliable finish.

-

Secure & Vibration-Resistant Connection: The M16 threaded collar locks the connection firmly in place, preventing accidental disconnection from movement or vibration, which is critical in environments with fans and ventilation systems.

Ideal for Use In:

-

Indoor Grow Rooms & Vertical Farms

-

Greenhouses & Hydroponic Systems

-

Commercial Horticulture Lighting Installations

-

Connecting LED Drivers to Light Engines

-

Any application requiring a reliable, waterproof power connection

Specifications:

-

Connector Type: M16 (16mm thread diameter)

-

Pin Count: 3-Pin (Live, Neutral, Ground)

-

Rating: IP67 (Waterproof and Dust-tight)

-

Contact Material: Gold-Plated Copper

-

Housing Material: Flame-Retardant PA66 (Nylon 66) Plastic

-

Approval: UL Listed / Recognized Component

-

Termination: Pre-soldered wire leads

Upgrade your grow operation’s infrastructure with a connector built for professionalism, safety, and unwavering performance. This assembly ensures your valuable LED lighting system receives clean, consistent power, protecting your investment and maximizing your yield potential.