Don’t Let Moisture Kill Your Connection: The Essential Guide to Electrical Waterproof Wire Connectors

From backyard lighting and marine applications to industrial machinery and automotive systems, electrical connections are everywhere. And wherever these connections exist, so does a silent threat: moisture. Water ingress is a leading cause of electrical failure, leading to short circuits, corrosion, and significant safety hazards. The solution? Investing in high-quality waterproof wire connectors.

Why Standard Connectors Aren’t Enough

Standard electrical connectors might work fine in a dry, controlled environment. However, when exposed to rain, humidity, splashing, or even submersion, they quickly become a weak link. Moisture can lead to:

-

Corrosion: Water and oxygen cause wire and terminal corrosion, increasing resistance and creating potential failure points.

-

Short Circuits: Water can bridge connections between positive and negative terminals, causing shorts that blow fuses or damage equipment.

-

Safety Risks: The combination of water and electricity is inherently dangerous, posing significant shock and fire risks.

Waterproof connectors are specifically engineered to create a sealed, protected environment for your electrical splices and terminations, ensuring system integrity and safety.

How Do Waterproof Connectors Work?

The effectiveness of a waterproof connector lies in its design, which typically incorporates multiple sealing features:

-

IP Rating: The key metric for waterproofing is the Ingress Protection (IP) rating. Look for a rating of IP67 or higher. IP67 means the unit is dust-tight and can withstand temporary immersion in water (up to 1m for 30 minutes). IP68 offers protection against prolonged immersion under higher pressure.

-

Sealing Grommets and O-Rings: These are the workhorses of waterproofing. High-quality silicone or rubber seals are integrated into the connector body. As the connector is assembled (often by a simple twisting motion), these seals compress around the wire jackets, creating a tight, water-resistant barrier.

-

Gel-Filled Design: Many modern connectors are filled with a waterproof silicone gel. This gel encapsulates the wire splice, blocking out all moisture and air to prevent oxidation and corrosion, even if the outer shell is compromised.

-

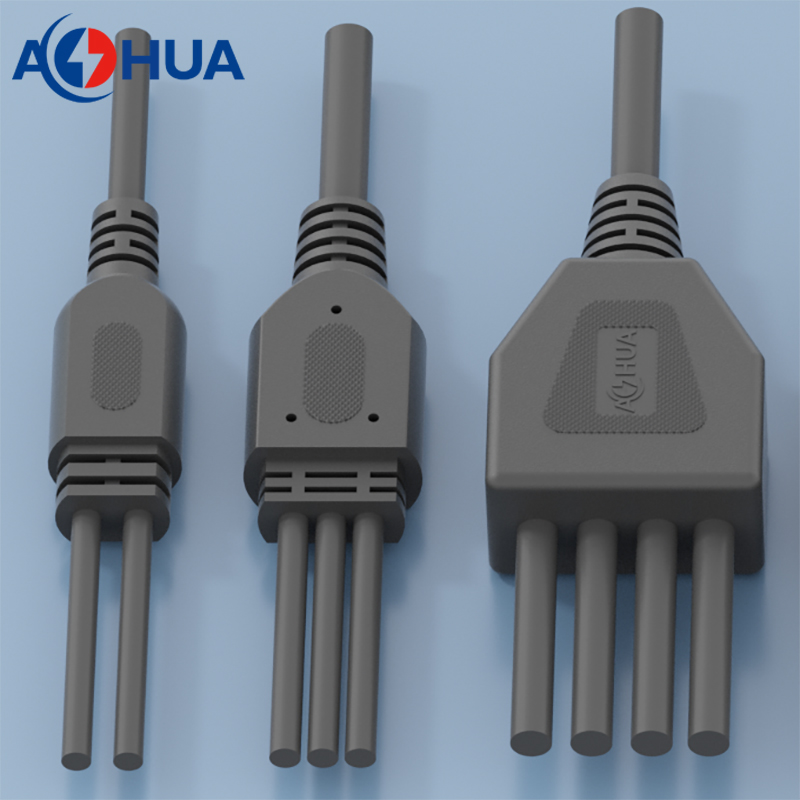

Durable Housing: The outer shell is typically made from tough, UV-resistant materials like nylon or PVC, protecting the internal connection from physical impact and environmental wear.

Key Applications for Waterproof Connectors

The versatility of these connectors makes them indispensable across numerous industries:

-

Automotive & Marine: Wiring for trailers, boat bilge pumps, navigation lights, and off-road vehicle electronics.

-

Landscape & Outdoor Lighting: Securing connections for LED strips, garden lights, pond pumps, and sprinkler systems.

-

Industrial Machinery: Protecting connections on equipment that requires wash-down or operates in damp environments.

-

Solar Power Systems: Connecting solar panels where they are exposed to the elements year-round.

Choosing the Right Connector

When selecting a waterproof connector, consider the wire gauge, the number of wires you need to connect, and the specific environmental challenges (e.g., will it be submerged?). Always ensure the product has a clear IP rating that matches your application’s demands.

Don’t leave your electrical projects to chance. By choosing the right waterproof connector, you invest in the longevity, performance, and safety of your entire system. Protect your connection, and your project will thrive for years to come.