Enhancing LED System Reliability: Crafting Waterproof Wire Harness Connectors

In the realm of LED systems, ensuring reliability and longevity is paramount, and a key player in this narrative is the waterproof wire harness connector. These connectors are the unsung heroes behind the scenes, safeguarding operations in diverse environments and conditions. Crafted with precision and adherence to quality standards, they play a crucial role in sustaining a seamless power supply for LED controllers. From outdoor installations to industrial settings, these waterproof wire harness connectors act as the backbone, guaranteeing uninterrupted functionality and protection against moisture, dust, and other elements.

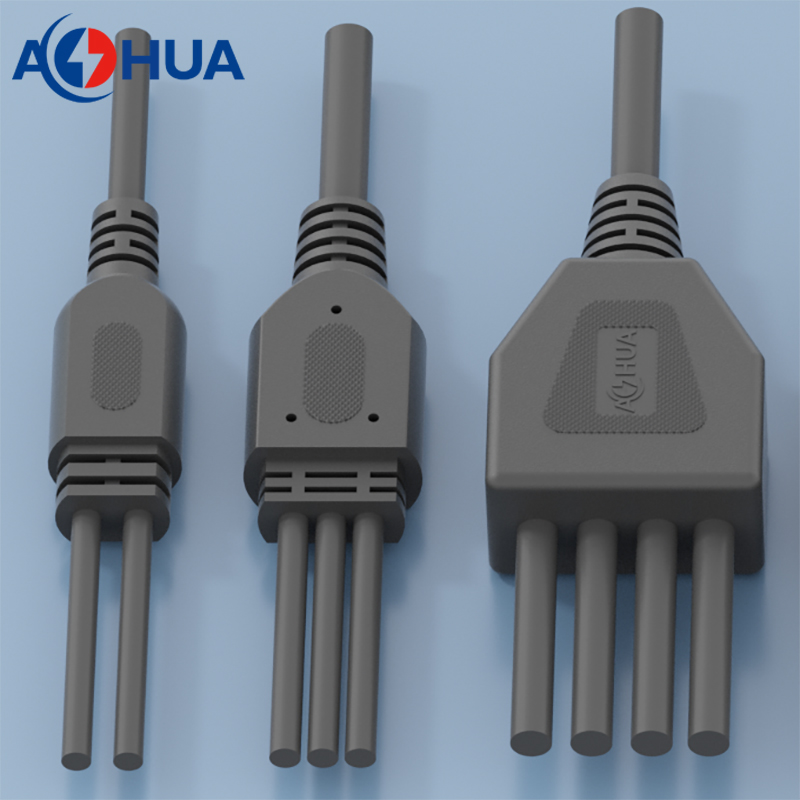

Material Innovation and Design Excellence

The essence of a robust waterproof wire harness connector lies in its construction. Made from high-quality materials such as durable plastics and resilient metals, these connectors withstand the rigors of both indoor and outdoor applications. With meticulous attention to detail in the molding process, they are fortified to combat water ingress, corrosion, and mechanical stress. The seamless integration of male and female connectors ensures a secure fit, promoting effective power transmission without compromise.

Tailored Solutions for Varied Needs

Customization is the cornerstone of modern connector solutions, and waterproof wire harness connectors are no exception. Offering versatility in design and functionality, these connectors cater to unique specifications, adapting to the demands of specific LED controller systems. Whether it’s solder and screw type connections or innovative assembly methods, these connectors provide a tailored approach to meet diverse requirements effectively.

Optimized for Performance and Durability

The efficiency of a waterproof wire harness connector lies in its ability to deliver consistent performance over an extended lifespan. Designed for longevity, these connectors undergo stringent quality checks to ensure reliability under challenging conditions. The integration of advanced sealing technologies and precision engineering guarantees protection against moisture and environmental factors, safeguarding the integrity of the LED system.

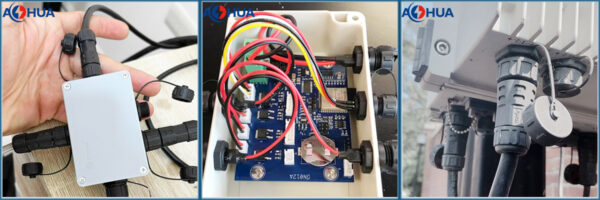

Application Across Industries

The versatility of waterproof wire harness connectors transcends industries, finding application in a multitude of settings. From architectural lighting schemes to automotive lighting systems, these connectors provide a seamless interface for LED controllers. Their adaptability makes them indispensable in diverse sectors, including marine, industrial, and agricultural domains, where reliable electrical connections are essential for optimal performance.

Conclusion:

In the realm of LED controller systems, the significance of waterproof wire harness connectors cannot be overstated. As the silent guardians of electrical connectivity, these connectors uphold the operational efficiency and longevity of LED installations. Their robust design, customized solutions, and application versatility make them indispensable components in modern electrical systems. By prioritizing innovation, quality, and performance, waterproof wire harness connectors pave the way for enhanced reliability and durability, ensuring the seamless function of LED systems in varied environments.