Ensuring Reliability in Dairy Tech: The Role of Waterproof Wiring Connectors in Milk Sensors

The integration of advanced technology into dairy farming has revolutionized the industry, enhancing efficiency, animal welfare, and milk quality. Central to this transformation are milk sensors, which monitor parameters like yield, temperature, and composition. However, the harsh environments of dairy farms—rife with moisture, cleaning chemicals, and fluctuating temperatures—demand robust components. Among these, waterproof wiring connectors emerge as unsung heroes, ensuring seamless data transmission and longevity of sensitive equipment.

Harsh Conditions Demand Robust Solutions

Dairy farms are inherently wet environments. Milking parlors undergo frequent high-pressure washdowns to maintain hygiene, and wearable sensors on cattle are exposed to rain, mud, and bodily fluids. Traditional electrical connections risk failure from corrosion, short circuits, or contamination, leading to data loss or equipment damage. Waterproof connectors mitigate these risks, enabling sensors to operate reliably despite constant exposure to liquids.

Key Features of Waterproof Connectors

- IP Ratings: Connectors are graded by Ingress Protection (IP) ratings. IP67 (resistant to temporary immersion) and IP68 (withstands prolonged submersion) are common standards, ensuring protection during washdowns or in humid barns.

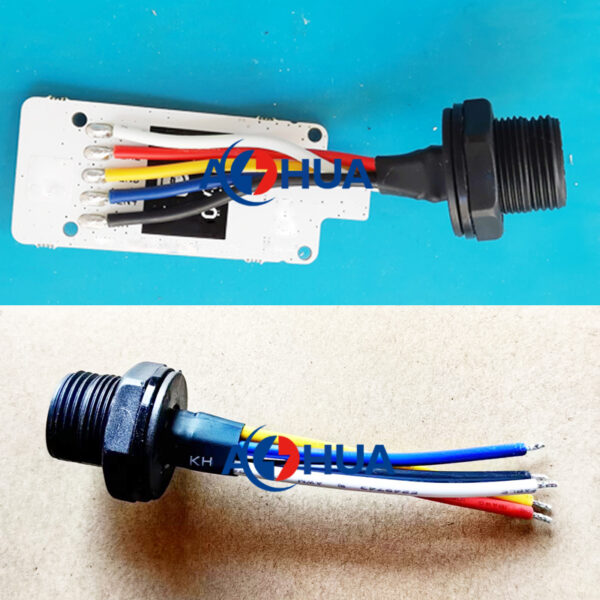

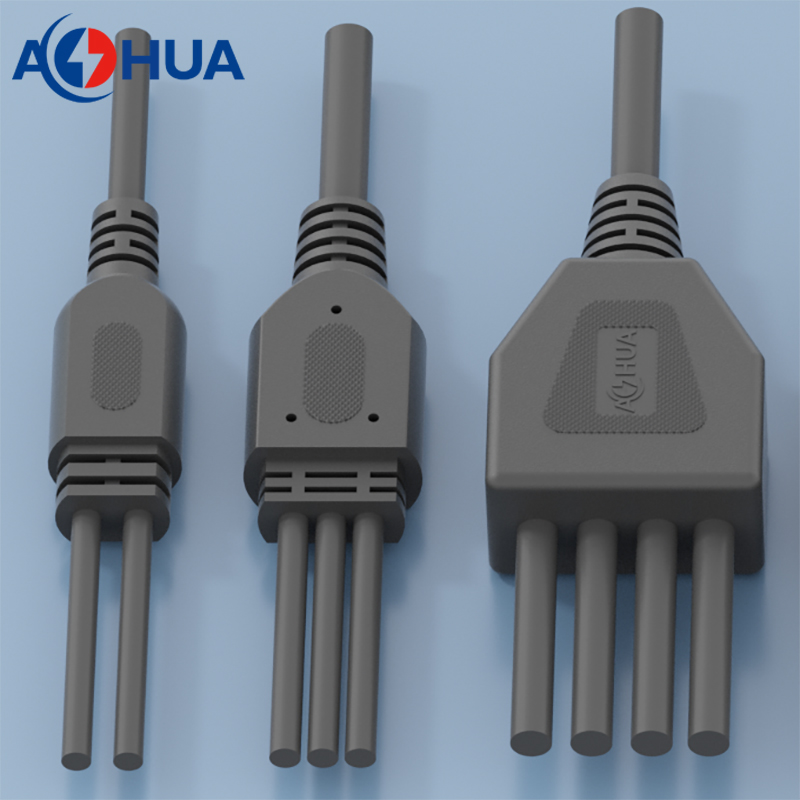

- Durable Materials: Constructed from thermoplastics, silicone, or corrosion-resistant metals, these connectors endure physical stress and chemical exposure from sanitizers.

- Sealing Mechanisms: Features like rubber gaskets, O-rings, or epoxy potting create watertight seals. Some designs include locking mechanisms to prevent accidental disconnection.

Benefits Beyond Water Resistance

Waterproof connectors offer multifaceted advantages:

- Reliability: Consistent performance ensures accurate, real-time data critical for monitoring herd health and milk quality.

- Durability: Reduced maintenance needs lower long-term costs and downtime.

- Safety: Preventing electrical leaks protects livestock and workers in wet conditions.

- Versatility: Compatible with various sensor types, from in-line flow meters to wearable health monitors.

Applications in Modern Dairy Farming

- Milk sensors serve diverse roles, each reliant on waterproof connectors:

- In-Line Milking Systems: Sensors tracking milk flow and composition integrate connectors that withstand daily wash cycles.

- Wearable Health Monitors: Collars or leg bands measuring activity levels or body temperature use flexible, water-resistant connectors to endure outdoor conditions.

- Milk Storage Tanks: Sensors monitoring temperature and somatic cell counts depend on connectors that resist condensation and chemical exposure.

Future-Proofing Dairy Technology

As dairy farms embrace IoT and automation, the demand for resilient infrastructure grows. Innovations like wireless sensors may reduce physical connections, but wired systems remain vital for high-data applications. Future connectors could integrate self-cleaning coatings or enhanced materials for extreme temperatures, further bolstering reliability.

Waterproof wiring connectors are pivotal in bridging the gap between cutting-edge sensor technology and the demanding realities of dairy farming. By ensuring uninterrupted operation in wet environments, they safeguard data integrity, equipment investment, and operational efficiency. As the industry advances toward smarter, more sustainable practices, these small yet vital components will continue to underpin the success of dairy tech, fostering a future where precision agriculture meets unwavering reliability.