How to learn about AOHUA waterproof connectors?

Let us go to the channel AOHUA waterproof connectors. In this article, we will learn about the classification of waterproof connector and the process of how to produce these waterproof connectors, and etc.

In AOHUA, there are many types of waterproof connectors in docking, connection and materials. Following text, we will talk about AOHUA waterproof connectors about docking, connection and materials.

First let us move forward to talk about Male Female Docking

When it comes to the docking type, we know the docking type means that the male to female pluggable type, which have to be male to female connector. They are include screw thread docking, push-locking docking, and quick docking. Let us make a more detailed explanation for these docking type:

Screw threads docking: the screw threads waterproof connector is male and femele connector coming with coupling thread, what exactly appearance is male or female connector with outside threads or inside threads. In general, the male connector is outside threads and female is inside threads. Surely, there is also a connector with reverse screw teeth that is male with inside threads and female with outside threads. This screw threads type connector should be screwing at the end of threads then finish. The below picture will tell you the details for threads of male and female.

Push-locking docking: the push locking type is there is bump and notch replacing of the screw threads, which require screw easy and locking, it is more convenient comparing to the screw threads type connectors. In the rapidly development, most people require faster and faster for docking waterproof connectors. The screw threads docking seemed to be much longer time for pluggable. Then push-locking waterproof connectors become more and more popular. Checking the details according to below picture.

Quick docking: the quick docking connector that is the male conenctor directly plug into female connector, no threads and no bump or notch. It is the fastest docking methods. Though it is the fast, but its features are also very obvious. For example one, this series connector is no coupling nut. That mean the quick docking connector will be not good waterproof. The second feature is the grasping force for mating male and female is not strong, and can not bear the weight. Its usually use in the connection that is no weight lifting.

Then go ahead to learn about connection type for AOHUA waterproof connector.

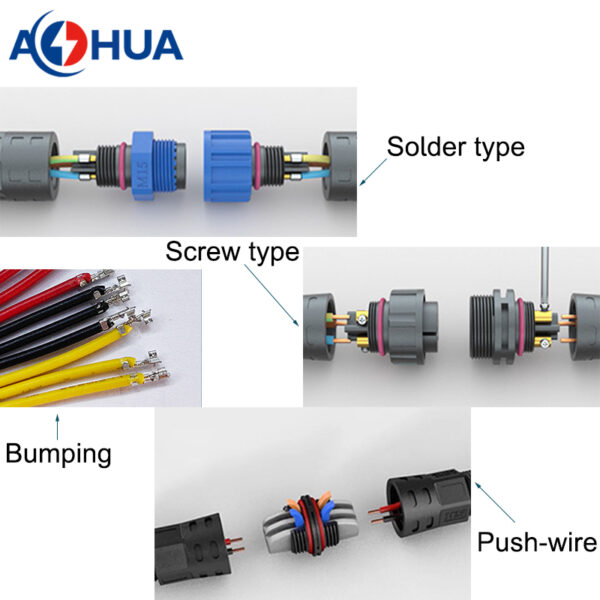

Once refer to the connection for waterproof connector, its usually means that the wire connection on terminals of waterproof connector. There are four types of connections at least. Such as soldering, screwing, push-wiring, crimping. For the over molding waterproof connector, we have solder, screwing or crimping type. Also we have screwing, soldering and push-wiring type. In usually, the assembly waterproof connector is coming without cable and the connector will be assembled in field, so customer will consider the wiring method. To be specific, the screw type or push-wire type connector will be easy do wiring operation in field assembly, while the solder type connector will require tin and electrical soldering iron for helping operation. In comparison, the molding connector will be solder type or crimping type(bumping type), rarely use screw type. Surely, the final choice should be made according to the request from clients.

Finally, Different materials makes different quality level waterproof connectors.

There are PVC, PA66, metal, and PVC mixed PA66 materials for injections in general. As a rule, the PVC cable mold with PVC material, the rubber or high temperature cable mold with PA66 mateiral. In some special usage, we also use the mixed materials for different request.

This part, we will talk about the processes of making waterproof connectors. In fact, the classification of waterproof connectors not only by docking, connection or materials, but also classified by different types of connectors. So here, we learn about the connector classification from connector types and the processes of productions.

The connectors can be divided into connector without cable, and connector with cable. The connector without cable means the connector is assmebly type and coming without cable, and we usually call it assembly connectors. While the connector with cable is the connector molded with cable directly, so it is coming with cable, and we generally call it molding connectors.

The following steps, we will move forward to learn about the processes of producing waterproof connectors.

- Assembly connectors:

Making conductor–injecting housing of connector–conductor pressing–assembly components–testing&checking–finished products.

- Molding connectors:

Cable making–conductor manufacture–cable cutting–wire stripping–soldering/bumping–connector injection–testing & checking.

The waterproof connectors seems to be easy and simple, but in fact, there are many factors for customization. The connectors can be design in many types and create different solutions. In summary, different docking, connection and materials with different connectors, also will require different processes. In AOHUA, it is precisely because we have many different products that we can come up with a vast number of cable solutions. Therefore, we can assist our clients in implementing various types of cable solutions.

Contact AOHUA here, let us make your dreams coming true. www.aohuadz.com, molly@aohuadz.com.