Inline Molding M8 22 24 AWG Extension Waterproof IP65 Sensor M8 Connector 3pin For Smart Camera

Inline Molding M8 22 24 AWG Extension Waterproof IP65 Sensor M8 Connector 3pin For Smart Camera

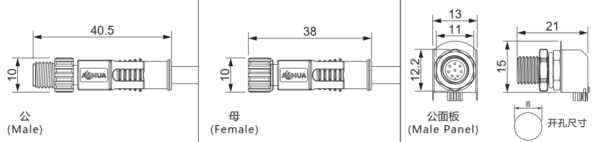

- M8 Connector

- Contacts: 3pin

- Male Panel Plug: customize for PCB

- Female: molded with cable

- Wire Gauge: 20 22 24AWG

- Cable Length: customized

- Color: white and black

- Shipping Port: Shenzhen China

- Payment Terms: T/T bank, Paypal

Share to:

Inline Molding M8 22 24 AWG Extension Waterproof IP65 Sensor M8 Connector 3pin For Smart Camera

This is inline Male Female sensor connector 3pin, which is molded with cable directly.

- Model: M08-03

- Contacts: 3pin

- Rated Voltage: 110V

- Rated Current: 4A

- Wire Gauge: 22 24AWG

- Cable OD: 3-5mm

- Cable Length: customized as required.

Hightlights

- Metal mechanism structure, and metal thread locking.

- Anti-vibration locking designing.

- Male to female, easy for connect and disconnect.

- IP65 Waterprorof Grades.

- Accept ODM & OEM, customize your required solution.

Elbow Type |

PCB Panel Type |

Inline Type |

How to order?

- conform the connector you need.

- specify the wire gauge and cable length you need

- specify the details you want to customize, such as stripped, tinned, or customized the panel plug on your PCB size.

- it would be much appreciated if you can provide the 3D files of PCB, then we can design the panel plug as your PCB.

When it comes to customizing a sensor M8 connector, there are several factors to consider to ensure a precise and reliable connection. Below are some key points to keep in mind when customizing a sensor M8 connector:

-

Pin Configuration: Determine the required pin configuration based on the specific sensor application. Sensor M8 connectors typically come in 3-pin or 4-pin configurations, with each pin serving a specific purpose such as power, ground, and signal transmission.

-

Cable Gauge and Length: Choose the appropriate cable gauge and length based on the power and signal requirements of the sensor. Ensure that the cable is of sufficient thickness to carry the required current and that the length is suitable for the application.

-

Cable Type and Protection: Select a cable type that meets the environmental conditions of the application. Consider factors such as flexibility, chemical resistance, and temperature rating. Additionally, ensure that the cable is adequately protected to withstand mechanical stresses and moisture ingress.

-

Connector Type: There are various connector types available for M8 connectors, such as straight or angled configurations. Consider the space constraints and the orientation needed for the sensor installation when selecting the connector type.

-

IP Rating: Determine the required IP rating for the sensor M8 connector based on the application environment. Higher IP ratings indicate better protection against dust and moisture. Common IP ratings for sensor connectors include IP67 and IP68.

-

Color Coding and Labeling: Consider customizing the connector with color coding or labeling to facilitate easy identification and installation. This can help to streamline the wiring process and reduce the chances of errors during installation or maintenance.

-

Compliance Standards: Ensure that the custom sensor M8 connector complies with the relevant industry standards and certifications. This helps to ensure the quality and reliability of the connector in the intended application.

-

Compatibility: Confirm that the custom connector is compatible with the sensor and the corresponding mating connector. Verify the pin layout and the electrical specifications to ensure a seamless and secure connection.

When customizing a sensor M8 connector, it is essential to work closely with an experienced manufacturer or supplier who can provide guidance and expertise in designing and producing a tailored solution. This will help to ensure that the custom connector meets the specific requirements of the sensor application in terms of performance, durability and reliability.

In AOHUA, customization is our culture, we can customize most types of cable wire solutions for LED lighting power and signal. Don’t hesitate to contact me if you have any request for cable wire harness.