Waterproof Connectors in Breeding Industries: Custom Solutions for Diverse Applications

Hi, today let us talk about the waterproof connectors in breeding industries.

In modern breeding industries—from high-tech aquaculture to automated poultry farms—the demand for reliable electrical connectivity in wet, corrosive, and dynamic environments has never been higher. Waterproof connectors, engineered to withstand harsh conditions while ensuring uninterrupted power and data transmission, are becoming indispensable tools. This article explores their critical role across breeding sectors and how bespoke ODM/OEM solutions empower businesses to tackle unique operational challenges.

- Breeding industry applications: where waterproof connectors thrive

Aquaculture & marine breeding

- Challenge: soltwater corrosion, tidal pressure, and biofouling

- Solutions:

316L Stainless Steel Connectors: Resist salt spray and microbial growth.

IP68/IP69K Submersible Plugs: Maintain sensor networks for water quality (pH, oxygen levels).

Quick-Mating Hybrid Connectors: Transmit power + data for automated feeders and drones.

Poultry & Livestock Farming

Challenge: High humidity, ammonia exposure, and frequent washdowns.

Solutions:

Chemical-Resistant TPU Housings: Withstand disinfectants and organic acids.

UV-Stabilized Cable Glands: For outdoor heating/ventilation systems.

Anti-Pecking Designs: Reinforced connectors to prevent damage from livestock.

Insect & Lab-Grown Protein Farms

Challenge: Precision climate control and sterility.

Solutions:

Medical-Grade Seals: IP67-rated connectors for humidity/temperature sensors.

EMI-Shielded Connectors: Protect data integrity in automated bioreactors.

- Cross-Industry Waterproof Connector Applications

While breeding industries have specialized needs, waterproof connectors also drive innovation in:

Agricultural Tech (AgTech)

Smart Irrigation: IP67 connectors for soil moisture sensors in flooded fields.

Drones: Lightweight M8/M12 connectors for crop-spraying UAVs.

Renewable Energy

Aquatic Solar Farms: Floating PV systems using submersible DC connectors.

Biogas Plants: Explosion-proof connectors for methane monitoring.

Industrial Automation

Food Processing: Stainless steel connectors meeting HACCP washdown standards.

Wastewater Treatment: Connectors resistant to H2S gas and sludge.

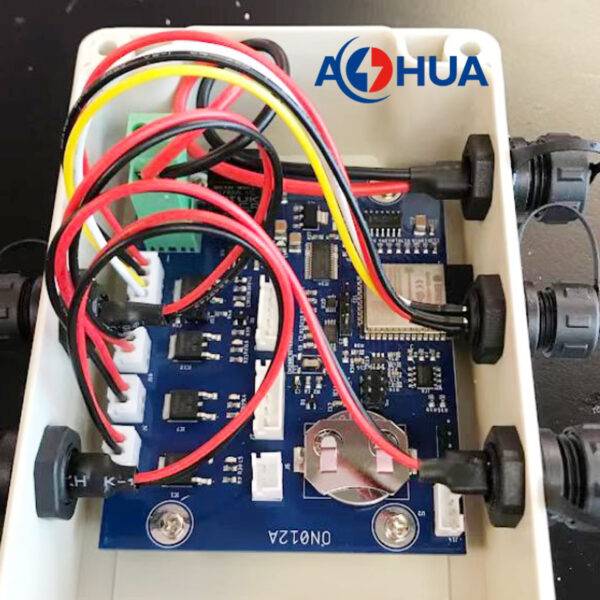

- Bespoke ODM/OEM: Tailoring Connectors to Your DNA

No two breeding operations are identical. Customization bridges the gap between standard products and unique needs:

Mechanical Customization

Shape & Size: Angled (90°/45°) connectors for tight equipment layouts.

Hybrid Configurations: Combine power, data (RS485/CAN bus), and fluid lines in one housing.

Material Innovation

Aquaculture: Buoyant foam-filled connectors for floating cages.

Cold Storage Farms: Silicone jackets stable at -60°C.

Smart Features

IoT-Enabled Connectors: Built-in sensors for real-time corrosion monitoring.

Color-Coding Systems: Simplify maintenance in multi-zone facilities.

Certification Compliance

Global Standards: Design connectors pre-certified for UL, CE, ATEX, etc.

Breeding-Specific: Meet ASC (Aquaculture Stewardship Council) or GLOBALG.A.P. guidelines.

- The ODM/OEM Advantage: From Concept to Reality

Partnering with a skilled manufacturer unlocks:

Rapid Prototyping: 3D-printed samples in 72 hours for field testing.

Cost Optimization: Bulk pricing for high-volume orders (50k+ units).

Supply Chain Integration: Kanban systems for just-in-time delivery.

Lifecycle Support: Connector retrofits for legacy equipment.

Why Custom Waterproof Connectors Matter

In breeding industries where margins are slim and downtime costs soar, off-the-shelf solutions often fall short. Bespoke waterproof connectors act as biological safeguards—ensuring sensors, pumps, and automation systems survive in environments that test the limits of engineering.

Explore Our Capabilities:

- Free Design Consultation: Adapt connectors to your equipment’s “genetics”.

- Test Reports Support: Prove quality and safetybefore deployment.

- One-stop R&D Support

By addressing niche requirements while leveraging cross-industry expertise, tailored waterproof connectors are redefining reliability in the world’s most demanding breeding environments.

In AOHUA, we can bespoke all what you want, ODM OEM or design molds, customize LOGO or printing, and so on, all of these are within the scope of our production business. It will be great appreciated if you can chat with our teams.