Customized IP68 Waterproof Junction Box For Power System Electrical Wire

In today’s ever-expanding world of electronic devices and intricate power systems, the need for reliable waterproof connectors is more important than ever. Whether it’s for outdoor applications or in environments exposed to moisture and dust, a waterproof junction box with a high IP68 rating is crucial for ensuring the safety and functionality of the connected components. This article explores the key considerations and design principles behind creating a customized waterproof junction box with IP68 protection.

The IP (Ingress Protection) rating system is used to classify the level of protection provided by electrical enclosures against solid particles and liquids. The IP68 rating is the highest level of waterproof protection available, indicating that the junction box is not only completely dust-tight but also capable of withstanding continuous immersion in water beyond 1 meter. Designing a junction box to meet this standard involves careful selection of materials, proper sealing techniques, and robust connectors.

To achieve optimal waterproofing, it is vital to select materials that are highly resistant to moisture and corrosion. The junction box should be constructed using high-quality stainless steel, aluminum, or engineering-grade plastics such as polycarbonate or ABS, depending on the specific application requirements. These materials offer excellent durability and resistance to harsh environmental conditions.

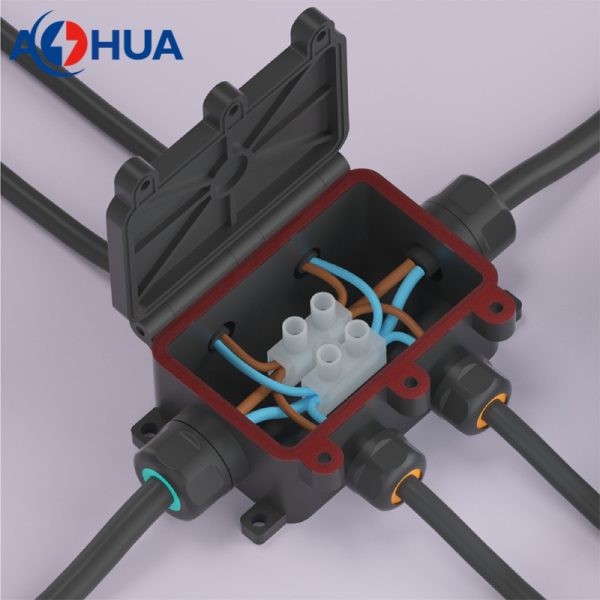

The success of a waterproof junction box lies in its ability to effectively seal against the ingress of water and other contaminants. This is achieved through various sealing techniques, such as gaskets, o-rings, or silicone seals. Gaskets made from materials like rubber or neoprene are commonly used to ensure a secure seal between the different components of the enclosure. O-rings, which provide a circular seal to prevent water penetration, are often used in conjunction with threaded connectors. Additionally, applying silicone sealant around cable entry points and other vulnerable areas enhances the overall waterproof integrity of the junction box.

The choice of connectors plays a vital role in achieving reliable waterproofing. Customized junction boxes for power signal splitters typically require 3-pin connectors capable of handling the electrical load while maintaining a watertight seal. These connectors should have a high IP rating (preferably IP68) and be specifically designed for outdoor or wet environments. Bayonet-style connectors, threaded connectors, or push-pull connectors are common choices due to their secure locking mechanisms and excellent sealing properties.

Proper installation and thorough testing are critical to ensure the waterproof integrity of the junction box. The box should include easy-to-use panel mounting options, allowing secure attachment to surfaces while maintaining a tight seal. Once installed, the junction box should undergo rigorous testing to confirm its IP68 rating. This includes subjecting it to simulated heavy rains, water submersion, and other demanding conditions to ensure it performs as expected in real-world scenarios.

Designing a customized waterproof junction box with an IP68 rating provides peace of mind for outdoor and high-moisture applications. By carefully selecting suitable materials, employing effective sealing techniques, and utilizing high-quality connectors, it’s possible to create a junction box that offers exceptional protection against water and dust ingress. Ensuring proper installation and conducting thorough testing guarantees its functionality and reliability over time. Invest in a well-designed waterproof junction box to safeguard your electrical connections and equipment, even in the harshest of environments.