High-quality Waterproof Electrical Connector used in Water Technology

We AOHUA, customize a wide range of connectors for various applications wihin the lighting technology industry, which are capable of withstanding even the most the challenging conditions of power running well. Our team of technical and sales will guide you through the whole customize process and buying process, and help you find a better solution that meets the needs of all your applications.

Role of Waterproof Electrical Connector in waterproof technology

In the world of water technology, where equipment is frequently exposed to water and other harsh elements, reliable and high-performance electrical connectors are paramount. These connectors ensure safe and uninterrupted power transmission, even in challenging environments. In this article, we will explore the importance of waterproof electrical connectors in water technology applications, their key features, and the benefits they provide.

Water technology encompasses a wide range of industries, including water treatment plants, swimming pools, fountains, and irrigation systems. Each of these applications requires robust electrical connections that can withstand moisture, humidity, and even submersion. This is where waterproof electrical connectors come into play.

One of the essential characteristics of these connectors is their waterproof rating, typically defined using the IP (Ingress Protection) standard. A commonly used rating for waterproof connectors is IP67, indicating protection against dust and water immersion up to 1 meter for a limited time. This level of protection ensures the reliability and longevity of the electrical connection, even in demanding water technology environments.

The construction and materials of waterproof electrical connectors contribute significantly to their performance. These connectors are typically engineered with rugged housing made from materials like PVC (Polyvinyl Chloride) or nylon, which provide excellent durability and resistance to corrosion. The connector pins are often made from high-quality metals, such as brass or stainless steel, to ensure reliable electrical conductivity and minimize signal loss.

One of the notable advantages of waterproof electrical connectors is their ease of installation. These connectors are designed for quick and simple assembly, allowing for efficient wiring and reducing installation time. This is particularly crucial in water technology applications where time is of the essence, such as in emergencies or time-sensitive projects.

Moreover, waterproof electrical connectors offer the ability to create secure and watertight connections. The connectors typically feature locking mechanisms, such as threaded couplings or snap-in designs, to ensure a tight fit and prevent accidental disconnection. This reliability is crucial in water technology applications, where even a minor interruption in power can have significant consequences.

In addition to their waterproof capabilities, these connectors often come with additional features to enhance their performance. For instance, some connectors may have built-in strain relief to provide added protection against cable tension and prevent wire breakage. Others may feature integrated sealing gaskets or O-rings to ensure a watertight seal and minimize the risk of water ingress.

The benefits of using waterproof electrical connectors in water technology applications are numerous. These connectors provide a secure and reliable electrical connection in moist and challenging environments, ensuring uninterrupted power supply. They also contribute to increased safety by reducing the risk of electrical short circuits, which could lead to equipment damage or even personal injury. Furthermore, their durability and weather resistance contribute to the longevity of the electrical system, reducing maintenance and replacement costs.

In conclusion, waterproof electrical connectors play a critical role in water technology applications. They provide the necessary protection against water and moisture, ensuring safe and reliable electrical connections. With their robust construction, ease of installation, and additional features, these connectors offer comprehensive solutions for powering various equipment in water-related industries. By investing in high-quality waterproof electrical connectors, businesses and professionals in the water technology field can optimize their operations and deliver superior results.

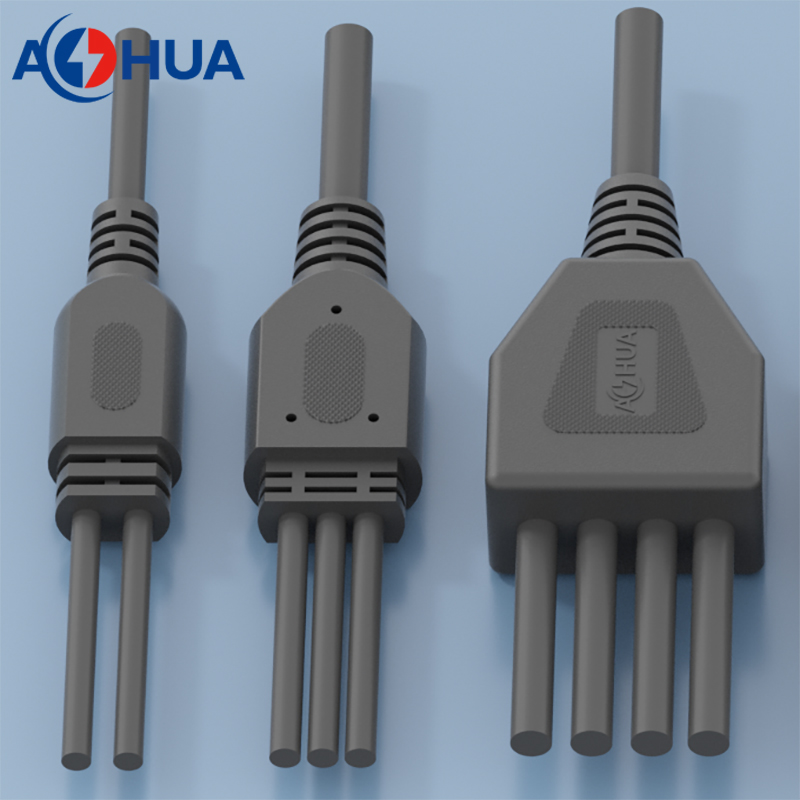

Recommended AOHUA Waterproof Electrical Connectors

Assembly type: assembled waterproof connectors are the only connector without cable that is used the your own bare wire exsiting;

Over-molding type: the over molding connectors are the connectors are molded with cable, which is used to the power and devices directly.

Choosing the right waterproof electrical connectors for your devices to gain the better waterproof effect and keep your power running well, which is increase efficiency and reduce wastage.

If your require a high quality and good waterproof performance electrical connectors for your systems, AOHUA provides a leading selection of decision. We are also advice you on a face-to-face discussion or meeting when appropriate.

If your company is involved the water technology and waterproof connector industry, please you can find out more about AOHUA products and services simply by getting in touch. Email AOHUA connector on molly@aohuadz.com, or call +86-15977341750, or complete inquiry form and we will get back to you with drawing and price within 24 hours.