Signal Waterproof Connectors: The Lifeline of Reliable Communication in Extreme Environments

In an increasingly connected world, the integrity of signal transmission can mean the difference between seamless operations and catastrophic failures. Whether it’s a subsea sensor transmitting data from ocean depths or a medical device operating in sterilized environments, signal waterproof connectors serve as the critical bridge that ensures uninterrupted communication. For industries where moisture, dust, and extreme temperatures are constant threats, choosing the right waterproof connector isn’t just an option—it’s a necessity.

Why Signal Waterproof Connectors Are Non-Negotiable

Signal transmission is highly sensitive to environmental interference. Even trace moisture can corrode contacts, disrupt data flow, or cause permanent damage. Consider these scenarios:

A factory robot’s control signal fails due to humidity, triggering production downtime.

A marine navigation system malfunctions during a storm, risking vessel safety.

An outdoor 5G base station degrades in monsoon rains, disrupting connectivity.

Signal waterproof connectors (rated IP67, IP68, or IP69K) combat these risks with:

Hermetic Sealing: Multi-layer gaskets and O-rings block water ingress.

EMI/RFI Shielding: Protect low-voltage signals from electromagnetic interference.

Corrosion Resistance: Gold-plated contacts and stainless steel housings for longevity.

Cutting-Edge Technologies Redefining Reliability

Modern signal waterproof connectors integrate innovations to meet evolving demands:

1. Hybrid Power + Data Transmission

Combine 10Gbps Ethernet with 30A power in a single IP68-rated unit, reducing cable clutter in IoT devices.

Example: Underwater drones using hybrid connectors for simultaneous HD video streaming and thruster control.

2. Nano-Coated PCB Contacts

Atomic-layer-deposited coatings prevent dendritic growth in humid conditions, critical for medical imaging equipment.

3. Quick-Mating Circular Connectors

Push-pull locking mechanisms enable one-handed operation in tight spaces, ideal for field service technicians.

Material Science Meets Durability

The right materials ensure performance under stress:

| Material | Best Use Cases | Key Advantage |

| Stainless Steel | Offshore/marine environments | Saltwater corrosion resistance |

| PBT Thermoplastic | Industrial automation | UL94 V-0 flame retardancy |

| Silicone-Sealed | Wearable medical devices | Flexibility + biocompatibility |

| Ceramic-Filled | High-voltage EV systems | Arc resistance up to 1,000V |

Industry Applications Driving Demand

Automotive: Waterproof CAN bus connectors for ADAS systems in self-driving cars.

Telecom: IP69K-rated fiber optic joints for 5G towers in typhoon-prone regions.

Energy: Submersible connectors for offshore wind farm monitoring sensors.

Healthcare: Sterilizable connectors for MRI machines and surgical robots.

Case Study: A North Sea oil rig operator reduced signal faults by 68% after deploying ceramic-hybrid connectors rated for 300m depths.

How to Select the Optimal Signal Waterproof Connector

Assess Environmental Stressors

Salt spray? Choose 316L stainless steel.

High vibration? Opt for spring-loaded contacts.

Match IP Ratings to Use Cases

IP67: Temporary immersion (e.g., agricultural drones).

IP68: Permanent submersion (e.g., underwater ROVs).

IP69K: High-pressure washdown (e.g., food processing).

Verify Signal Integrity

Request insertion loss (<0.5dB) and VSWR (<1.5:1) test reports.

Prioritize Future-Proofing

Modular designs allow upgrades (e.g., adding PoE++ capability).

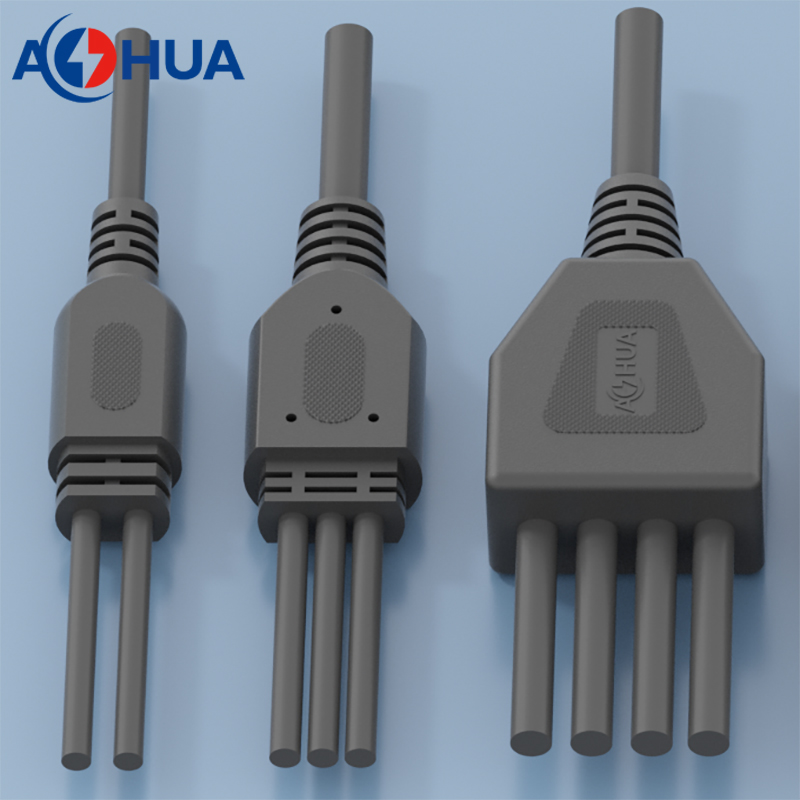

Why Choose AOHUA?

At AOHUA, we engineer signal waterproof connectors that exceed industry benchmarks:

Patented DualSeal™ Technology: Combines radial and axial sealing for leak-proof performance.

Customization: Tailor pin counts, shielding, and coatings to your specs.

Rigorous Testing: Each unit undergoes 1,000+ mating cycles and thermal shock trials (-40°C to 125°C).