IP68 Waterproof Electrical Connectors Is Unmatched Protection for Demanding Environments

In the intricate world of electrical systems, exposure to moisture, dust, dirt, vibration, and extreme temperatures is a constant threat. When failure is not an option – whether deep underwater, on a dusty construction site, or in a sterile washdown area – IP68 waterproof electrical connectors emerge as the definitive solution. These connectors represent the pinnacle of ingress protection, ensuring critical connections remain secure, reliable, and operational in the planet’s most unforgiving conditions.

Decoding IP68: The Gold Standard of Sealing

The “IP68” designation is defined by the International Electrotechnical Commission standard IEC 60529. This two-digit code provides a clear, internationally recognized measure of a device’s protection against solids and liquids:

First Digit (6): Dust-Tight. This is the highest level of protection against solid foreign objects. An IP6X connector is completely sealed against dust ingress, even under vacuum test conditions with fine talcum powder. No harmful dust penetration occurs.

Second Digit (8): Protected Against Continuous Immersion. This rating signifies the connector can withstand prolonged submersion in water under conditions specified by the manufacturer. Crucially, manufacturers define the exact depth (typically 1 meter or more, often up to 3 meters or deeper) and duration (commonly 30 minutes, but frequently extending to 24 hours or even indefinite submersion). It guarantees protection beyond temporary splashing or low-pressure jets.

Engineering Excellence: How IP68 Connectors Achieve Superior Sealing

Achieving this level of robust protection requires sophisticated design and precision manufacturing:

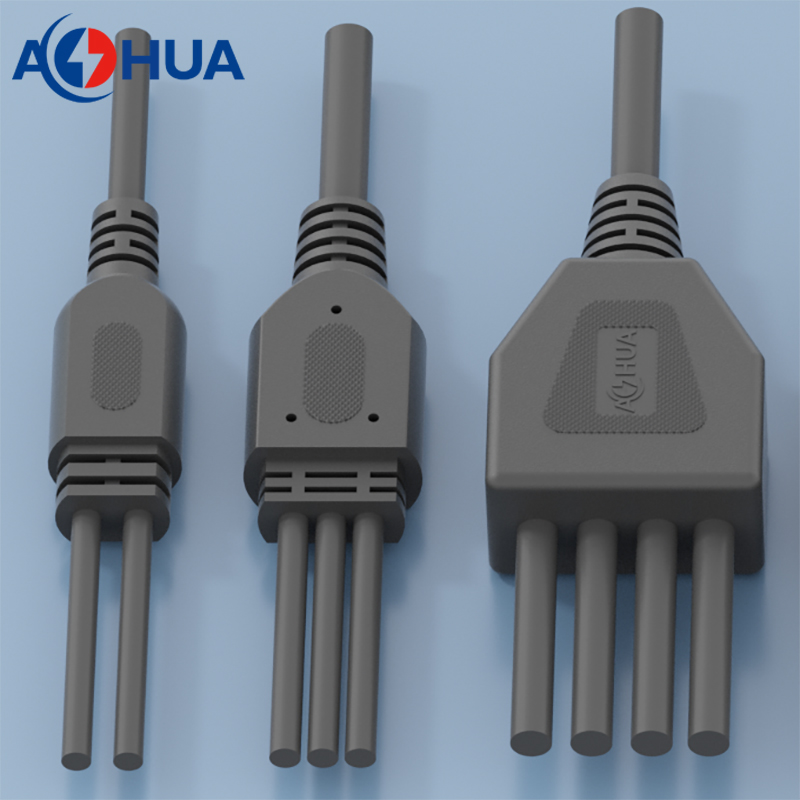

Multi-Point Sealing: High-quality elastomeric seals (O-rings, gaskets, gland seals) are meticulously placed at every potential entry point: between mating connector halves, around cable entries, and within the connector body itself. These create redundant, watertight barriers.

Rugged Construction: Housings are crafted from durable, often corrosion-resistant materials like engineering thermoplastics (PBT, PA), stainless steel, or brass. They are designed to resist impact, crushing forces, vibration, and UV degradation.

Secure Locking Mechanisms: Screw-thread (M-style), bayonet, or robust push-pull systems ensure a tight, vibration-proof, and watertight connection that won’t accidentally disconnect.

Internal Protection: Many IP68 connectors feature internal potting (filling with epoxy resin) or overmolded cable exits. This seals the internal terminals and wire connections, preventing water ingress along the cable strands and providing excellent strain relief.

Rigorous Validation: Genuine IP68 connectors undergo stringent testing per IEC 60529, including submersion at the specified depth and duration, dust chamber exposure, and often additional tests for temperature cycling, shock, and vibration.

Where IP68 Protection is Essential

The uncompromising sealing of IP68 connectors makes them indispensable across numerous critical industries:

Industrial Automation: Submersible sensors, robotic arms in washdown environments (food, beverage, pharma), outdoor machinery, mining equipment, wastewater treatment plants.

Marine & Offshore: Underwater lighting, sonar equipment, submersible pumps, navigation systems, sensors on buoys, offshore oil & gas instrumentation.

Outdoor Infrastructure: LED streetlights, traffic signals, landscape lighting, EV charging stations, solar panel junction boxes, wind turbine sensors (exposed nacelles/hubs).

Transportation: Railway signaling, sensors on heavy-duty vehicles and agricultural machinery, components in electric vehicles exposed to road spray.

Military & Defense: Equipment requiring operation in sand, mud, salt spray, and complete submersion.

Medical & Laboratory: Devices requiring sterilization via autoclaving or aggressive chemical cleaning.

Underwater Technology: ROVs (Remotely Operated Vehicles), AUVs (Autonomous Underwater Vehicles), diving equipment electronics, underwater cameras.

Selecting the Right IP68 Connector: Key Factors

Specific IP68 Rating: Always verify the manufacturer’s exact depth and duration specification (e.g., “IP68 @ 2m for 24 hours”).

Electrical Requirements: Ensure current, voltage, and signal integrity ratings meet your application needs.

Contact Configuration: Select the correct number and type of pins/sockets for power and data.

Cable Compatibility: Match the cable gland size to your cable’s outer diameter.

Environmental Resistance: Consider exposure to chemicals, oils, fuels, saltwater, extreme temperatures, or UV radiation.

Mechanical Durability: Assess needs for impact resistance, vibration tolerance, and mating cycle life.

Locking Mechanism: Choose based on required security, ease of use, and resistance to vibration loosening.

Certifications: Look for additional relevant certifications (e.g., UL, ATEX for hazardous areas, marine approvals).

IP68 waterproof electrical connectors are far more than just “water-resistant”; they are engineered fortresses for electrical connections. By delivering the highest practical levels of dust-tightness and protection against continuous water immersion, they provide unparalleled reliability where environmental challenges are severe. Investing in genuine, high-quality IP68 connectors is an investment in system uptime, safety, and longevity. When exposure to water, dust, or harsh conditions threatens your electrical connections, specifying IP68 is the proven path to ensuring uninterrupted performance and peace of mind. They are the essential link for technology operating at the edge of environmental endurance.