Solving Connectivity Challenges: The Critical Role of LED Waterproof Connectors

In the realm of LED lighting systems—whether for urban streetlights, architectural façades, or underwater displays—the reliability of electrical connections directly impacts performance, safety, and longevity. LED waterproof connectors emerge as engineered solutions to combat environmental threats while ensuring seamless power delivery. This article explores the core challenges these connectors address, their applications, and best practices for designing robust wire harness systems.

Key Problems Addressed by LED Waterproof Connectors

- Environmental Hazards:

Moisture & Water Ingress: Rain, humidity, or submersion can corrode contacts, causing short circuits.

Dust & Debris: Particulate accumulation disrupts conductivity, especially in deserts or construction zones.

Thermal Stress: Temperature swings (-40°C to +125°C) degrade non-resistant materials.

- Mechanical Challenges:

Vibration: Traffic-induced shaking in streetlights or industrial machinery loosens connections.

UV Degradation: Solar exposure cracks conventional plastics, compromising seals.

- Electrical Risks:

Current Leakage: Poor insulation in wet conditions risks electrocution.

Signal Interference: EMI/RFI in high-density LED arrays disrupts control systems.

Applications: Where Waterproof Connectors Shine

- Outdoor Lighting:

Streetlights, garden lamps, and stadium LEDs exposed to rain/snow.

- Marine & Underwater Systems:

Harbor lighting, pool LEDs, and subsea aquaculture monitoring.

- Automotive Lighting:

Waterproof connectors for headlights, brake lights, and EV charging ports.

- Industrial Facilities:

High-pressure washdown areas in food processing plants or chemical factories.

- Smart Cities:

IoT-enabled streetlights requiring data + power transmission.

Designing LED Waterproof Wire Solutions: A 5-Step Framework

- Material Selection

Housing:

Nylon 66: UV-stable, UL94 V-0 flame-retardant.

PBT (Polybutylene Terephthalate): Chemical/oil resistance for industrial use.

Seals:

Silicone O-rings (temperature flexibility) or FKM fluorocarbon (fuel/oil resistance).

Contacts:

Gold-plated brass (low resistance, anti-corrosion) for signal lines.

Silver-plated copper (high current capacity) for power lines.

- Mechanical Engineering

IP Rating Compliance:

IP67: Temporary submersion (e.g., flood-prone streetlights).

*IP68/IP69K*: Permanent underwater use or high-pressure cleaning.

Locking Mechanisms:

Screw-lock (MIL-DTL-5015) for vibration-prone environments.

Push-pull (M12/M16) for quick maintenance.

- Electrical Configuration

Wire Gauge: Match current load (e.g., 18 AWG for 10A @ 12V DC).

Shielding: Braided tinned copper + foil for EMI-sensitive LED controllers.

Voltage Isolation: Dual-wall insulation (XLPE) for 600V+ systems.

- Harness Assembly

Precision Crimping: Automated crimpers (e.g., Schleuniger) ensure <5mΩ resistance.

Overmolding:

TPU/PPA injection seals wire exits, preventing capillary water ingress.

Strain relief ribs reduce flex fatigue.

Testing Protocols:

HiPot Testing: 1,500V AC for 1 minute.

Salt Spray Testing: 500+ hours per ASTM B117.

- Customization & Scalability

ODM/OEM Services:

Adjust pin counts (2-24 pins), colors (RAL codes), or angles (30°-180°).

Integrate IoT sensors for smart lighting networks.

Certifications:

UL 1977, CE, RoHS, and REACH compliance for global markets.

Case Study: Revitalizing Coastal Street Lighting

Challenge: A seaside city’s LED streetlights faced 40% failure rates due to salt corrosion.

Solution:

IP68 connectors with 316L stainless steel housings and FKM seals.

Overmolded harnesses using marine-grade tinned copper wire.

Result: 98% operational uptime over 3 years, reducing maintenance costs by 60%.

Why It Matters

LED waterproof connectors are not mere accessories—they are the guardians of illumination integrity. By addressing environmental, mechanical, and electrical threats through precision engineering, they enable LED systems to deliver on their promise of efficiency and durability.

Partnering for Success: Collaborate with manufacturers offering in-house design support, rapid prototyping (72-hour samples), and lifecycle testing. In an era where lighting meets IoT and sustainability, the right connector ensures your LEDs shine brighter, longer.

In a words, the LED waterproof connector can solve most the problems of cable layout between power and equipments. Surely, this is why the connector should be birthed in the world.

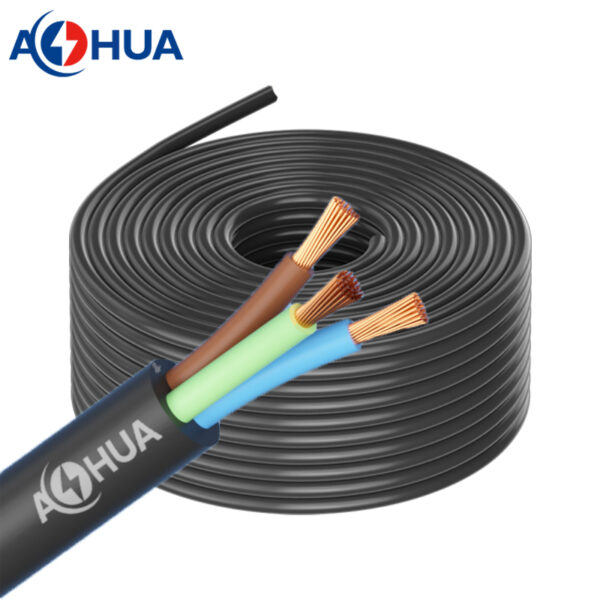

In AOHUA, we accept the business of led waterproof connector for design, manufacture and selling: from raw materials to products, we can make the toolings, hardware and conductors, cable wire and power cord, connector molding and assembly, testing and certificate, sell out and after-sell services, and so on. We can finish all processes from materials to products. And with more than 18 years’ experience, you can believe us, we are your best choices.

Let us start here: sales manager-Molly Mo, molly@aohuadz.com, more detail products from here: www.aohuadz.com .